Used to mount Woodman Agitators into steel drums.

2NCF

Patent #: 7318668

The 2NCF is used to keep the agitator centered in the top of the agitator drum and from coming off the pivot pin during transportation. Design Benefits:

- Allows 2″ flange to adapt to 1 1/2″ flange (Standard Air Motor Installation)

- Cleaner drum – Eliminates metal to metal contact

- Easier Installation

- 2NCF Spec

Top Bracket

Welded to the center of the drum lid the top bracket is designed to span either a 1 1/2″ or 2″ flange. The top bracket keeps the agitator centered in the lid of the agitator drum and the agitator from coming off the pivot pin during transportation.

#3NBB (Nylon Bottom Bearing)

Design to fit in the bottom of a #1 Pin or # 3 Series agitator. The Woodman #3NBB minimizes contamination by limiting metal to metal contact between the pivot pin and the bottom of the agitator.

3 Series agitator. The Woodman #3NBB minimizes contamination by limiting metal to metal contact between the pivot pin and the bottom of the agitator.

#44 NTB (Nylon Top Bearing)

The Woodman #44NTB was designed to minimize metal to metal contact between the agitator shaft and 1 1/2″ agitator bracket during transportation of an agitator drum.

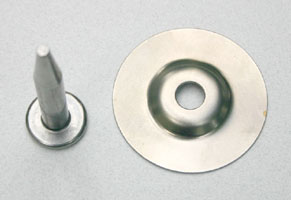

Tapered Pivot Pin & Retainer

The pivot pin and retainer are assembled together and then the retainer is resistance welded to the center of the drum bottom. The tube from the agitator is then inserted over the pivot pin. Pivot pins are the bearing surface for the #1 Pin and #3 series agitators.

Tapered Pivot Pin with Projections

Pivot Pins with projections are resistance welded to the center of the drum bottom. The tube from the agitator is then inserted over the pivot pin. Pivot pins are the bearing surface for the #1 Pin and #3 series agitators.